Gantry Crane Metal Fabrication

We have specialized in heavy duty hydraulic applications for over 40 years at Hyseco, Inc. Customers in demanding industries rely on us for durable, reliable equipment, well-illustrated by the following project. A customer in the offshore industry needed a gantry crane to be built and mounted on a seismic ship for the deployment of measuring equipment. The job required heavy duty materials and multiple components; all assembled into one unit. After visiting us and seeing other similar products that we had fabricated, this customer contracted us to complete the crane. We were pleased to accept the project, employing every level of our turnkey capabilities to complete construction on time and on budget.

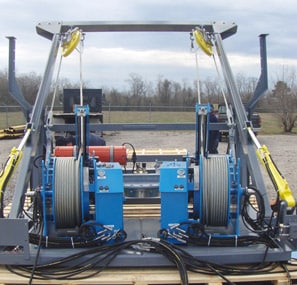

Using Socratic chrome rod, structural steel, flame cut plate, and S/S fittings, we began construction of this crane employing our best certified welders, hydraulic technicians, and machinists. We used our full range of welding, manual lathe machining, coating, and galvanizing capabilities to fabricate this crane. The completed crane consisted of components that included a custom built power unit, lifting sled, custom cylinders, crane frame, pulleys, winches, and hoses. We met our customer’s precise specifications, including a 7 ½ GPM hydraulic power unit, a control valve stand, and two 4” bore, 2” rod, 20 ¼” stroke, 300 PSI hydraulic cylinders with custom mounting eyes. Special primer and 3 part epoxy paint was used for finishing to protect the crane from harsh offshore conditions.

After construction was complete, we performed rigorous testing, including pull-testing the crane’s lifting eyes to 8000 lbs. each. We were able to complete this project within our quoted lead time, which for this type of project usually runs 8 to 12 weeks total, depending on material availability. Our customer was very pleased with this crane, and in addition to ordering several more units, has employed us to work on a new style gantry crane for them.

For additional information about this project or to learn how our capabilities can be put to work for you, please contact us directly.