CNC Machining for Oil & Gas Industry

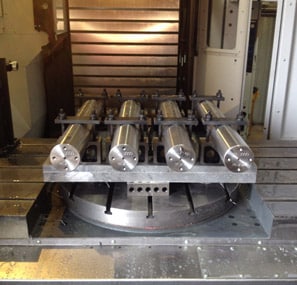

With our well-equipped machine and fabrication shop, Hyseco, Inc. has the ability to consistently produce high-quality parts that exceed our customers’ expectations. This often results in a lot of repeat business and has earned us a loyal customer base. One of our clients in the oilfield industry relies on us to supply them with various compensator parts. We manufactured these parts from a variety of different metals and applied several different finishing treatments.

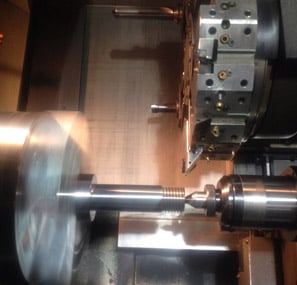

To machine the workpieces shown here, we used our high precision CNC lathe and CNC milling equipment. In addition to carbon steel, materials of construction include alloy steel and 660 bronze. With our knowledgeable staff and many years of experience, we are able to choose tools and setups to use our equipment at its maximum capacity. We specialize in developing efficient machining strategies to repeatably produce parts with close dimensional tolerances and excellent surface characteristics. We also focused our efforts on achieving good production speed and keeping costs to a minimum.

For some of the parts, finishing involved pre-treatment and black oxide finishing, which served to improve the corrosion resistance and provide a good surface for the additional priming and painting. Some of the other parts were also pre-treated and given a nickel-plated finish. All of the components were delivered to the client on specification, on time, and on budget.

To learn more about our precision machining capabilities and other industrial services, contact us today.